UV Powder For Plastics & Composites

There are many types of plastics, carbon fiber, and carbon fiber composites that can be successfully coated with UV cured powder coatings.

UV Cured Powder Coating on Plastics

UV cured powder coating requires only enough time and heat to melt the powder, an example being 130°C at 1-2 minutes, followed by UV cure. Once the part is exposed to UV light it is instantly cured.

The process speed and low temperatures allow plastics to be successfully finished without melting or deforming the part. Since plastic is a non-conductive material, a primer is used to promote adhesion on the surface of the part before powder application.

Applications Include

- Automotive

- Aerospace

- Industrial

- Electronics

- Household & More

UV Cured Powder Coating on Composites

Demand for energy efficient, electric and alternative use vehicles is accelerating the use of lightweight materials. Manufacturers are switching from steel and aluminum to carbon fiber which is lighter, stronger, and more resistant to corrosion than metals. Unlike metals, carbon materials do not require corrosion protection, but they do need to be finished for aesthetics and appearance.

The fast process time and low temperatures (example 130°C at 1-2 minutes) followed by instant UV cure, ensures that the integrity of the composite material is not compromised.

Applications Include

Automotive Alternate Use Vehicles Aerospace Sports & More

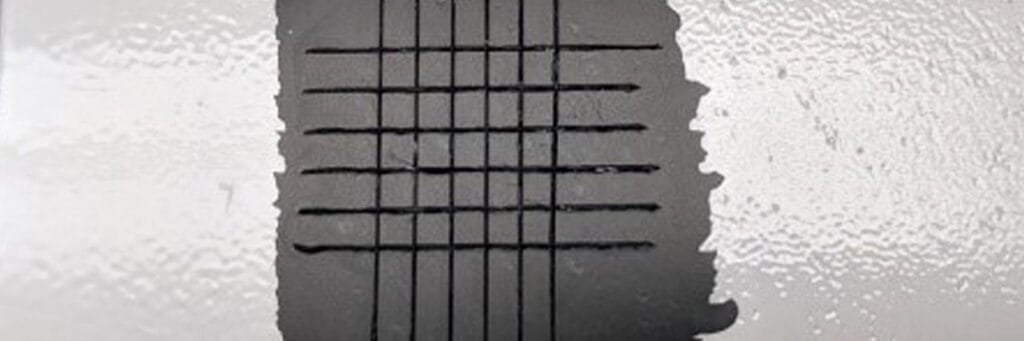

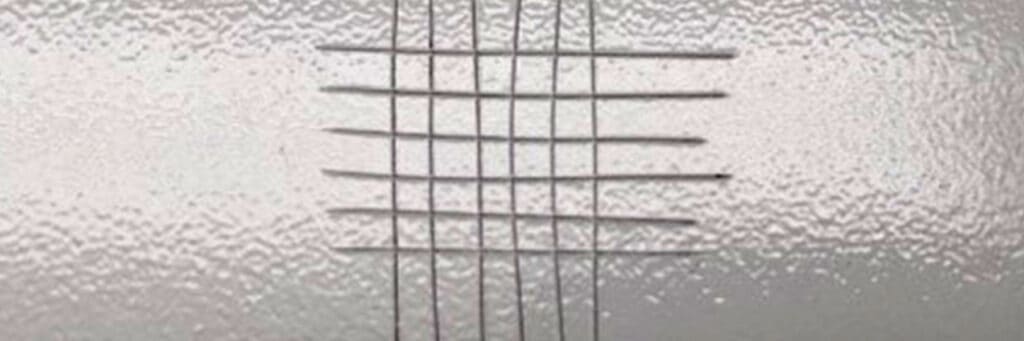

Surface Preparation for Plastics & Composites

There are several forms of pretreatment processes that can be used to prepare the surface of a part prior to UV powder coating application including liquid primer, plasma treating, media blasting, and sand blasting. These treatments are also adhesion promoters, increasing the wetting and flow of a coating onto the substrate. Without satisfactory adhesion the coating will fail and not meet the product’s performance requirements.

Available Colors and Products

Keyland Polymer can develop a custom powder to match both RAL and Pantone standards as well as customer supplied samples; including metallic and speckle finishes. Our in-house coating, formulation, and testing laboratory allows us to develop and validate coatings for your specific product application and performance requirements.